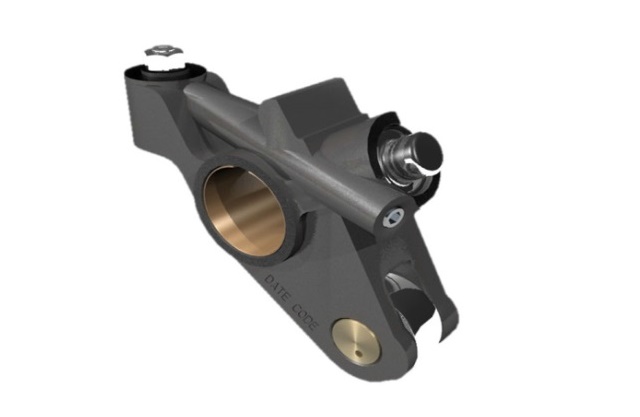

Jacobs Offers Improved Engine Brake for 2017 X15 Engine

Image: Jacobs Vehicle Systems

">Image: Jacobs Vehicle Systems

">Jacobs Vehicle Systems has announced an optimized engine brake for the 2017 Cummins X15 engine designed to add additional braking power from the engine compared to past models.

Improving on the design of the integrated Jake Brake for the 15-liter engine, the 2017 X15 engine offers around 10% additional braking power at engine speeds under 1,700 RPM. At a typical engine speed of 1500 RPM, drivers have access to 450 horsepower of braking power while in traffic or descending a hill.

With a downshift, the engine brake on the X15 Performance Series will deliver a retarding force of up to 600 horsepower at 2,100 RPM.

“With the Cummins X15, equipped with an integrated Jacobs Engine Brake, truckers will experience safer travel and the improved comfort they demand, while reducing the wear of foundation brakes, downtime and service costs,” said Steve Ernest, vice president, engineering and business development.

Related: Focus On... Cummins 2017 X15 Efficiency Series Engine [Video]

Follow @HDTrucking on Twitter

...Read the rest of this story